-

ProductsThe production site control and standardized assembly line are designed according to European standards. The products are divided into 8 series and 115 models.

-

Service SupportComps's service system covers all major and medium-sized cities across the country. Not only does the company have a complete service team, but it is also committed to developing and training professional dealers and service providers across the country to form a huge service network, ensuring that more than 80% of the country's cities and surrounding areas; service personnel arrive at the scene within 24 hours after receiving the notice.

-

NewsInnovation is the life of an enterprise. Comps pursues sustainable operation. Every year, 10% of sales are invested in joint technology research and development with professional colleges.

-

About UsShijiazhuang Comps Compressor Co., Ltd. was established in June 2004 with a registered capital of 35 million yuan. The company is located at 172 Nanche Road, Luancheng District, Shijiazhuang, Hebei Province. It is a high-tech enterprise integrating research and development, manufacturing, and marketing, and enjoys a high reputation in the industry. In 2017, Kangpu Compressor Co., Ltd. built a new factory area with an investment of 160 million yuan, covering a total area of 158 acres. The company's production and manufacturing center covers an area of 68 acres.

-

ApplicationThe service system of Comps company spreads all over the country, we have technical force and can make response to the actual needs of users.

What are the simple methods for measuring gas volume? How to operate and calculate.

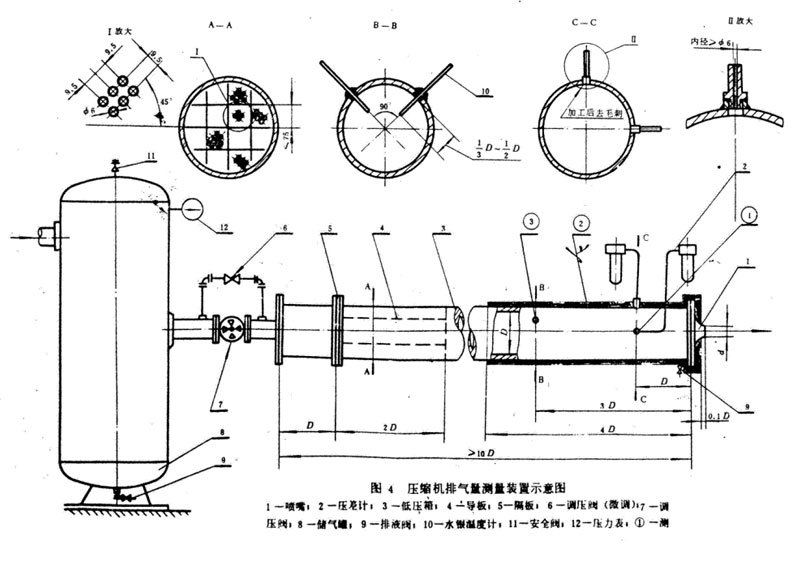

As the air volume of the air compressor is generally measured by using ASME nozzle measuring device to measure the flow of the compressor, as shown in the following figure:

However, as the field conditions cannot meet the test requirements, the more direct method is to use the tank filling method to roughly measure the exhaust volume. The specific methods are as follows:

1) Ensure that there is no long pipeline or other equipment pipeline affecting the volume from the air compressor to the air storage tank. If so, the volume shall be included.

2) There is no air leakage between the air compressor and the air storage tank. The air storage tank has a closed valve to hold the pressure and ensure that the valve does not leak. The pressure gauge on the air reservoir is good.

3) It is suggested that the adjustment of air compressor capacity adjustment fails to prevent the capacity adjustment from affecting the measured value during the test.

4) The frequency conversion or belt conveyor shall ensure that there shall be no speed drop caused by frequency conversion or belt slip under the rated speed of the head during the test.

5) The initial pressure is recommended to be above the opening pressure of the pressure maintenance valve, so as to prevent the calculation from being affected by the non opening of the pressure maintenance valve and avoid the influence on the gas calculation during the start-up loading process.

6) After the above conditions are met, close the exhaust ball valve of the air storage tank, start the air compressor and hold the stopwatch. For example, the opening pressure of the machine pressure maintenance valve is 4kgf and the rated pressure is 10kgf. We'd better calculate the time consumed by the air storage tank from P1 = 4.5kgf to P2 = 9.5kgf, t = 0.5 (min), and the volume of the air storage tank is v = 2m ³, Then the formula of air compressor exhaust volume is q = V (p2-p1-1) / T = 2 × (9.5-4.5-1)/0.5=16m ³/ min。 The above formula ignores the influence of temperature. If the gas temperature difference before and after tank filling is very large, the temperature should be taken into account in the calculation.

Scan the code to follow the official information

All rights reserved:Shijiazhuang Comps Compressor Co., Ltd 冀ICP备15000208号-1 Website building:300.cn Beijing SEOtag